World Motorsports - Titanium Lug Bolts

Designed to fit:

- 1999+ Porsche 911 (including all variants)

- 2005+ Porsche Cayman / Boxster (including all variants)

- 2002+ Porsche Cayenne (including all variants) Requires +5mm longer

- 2010+ Porsche Cayenne (including all variants) Requires +5mm longer

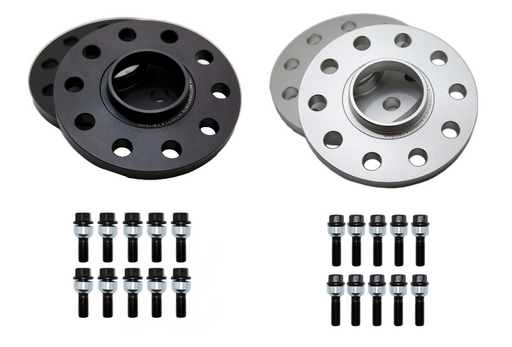

Note - Sold individually, 5 bolts are required per each wheel. Minimum order QTY 10

Product Details

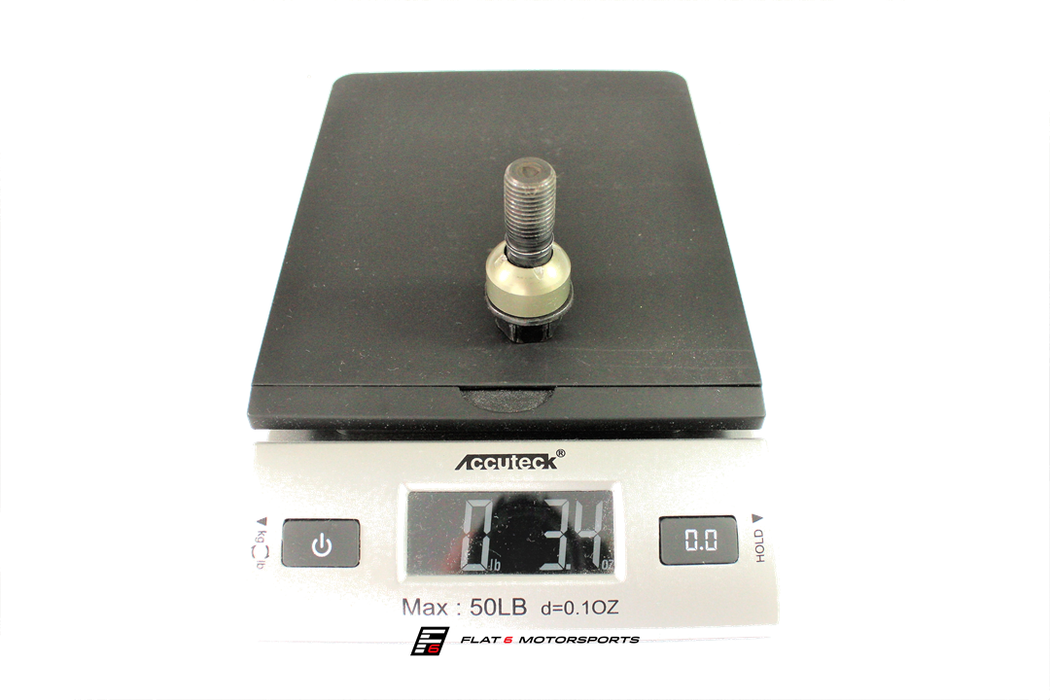

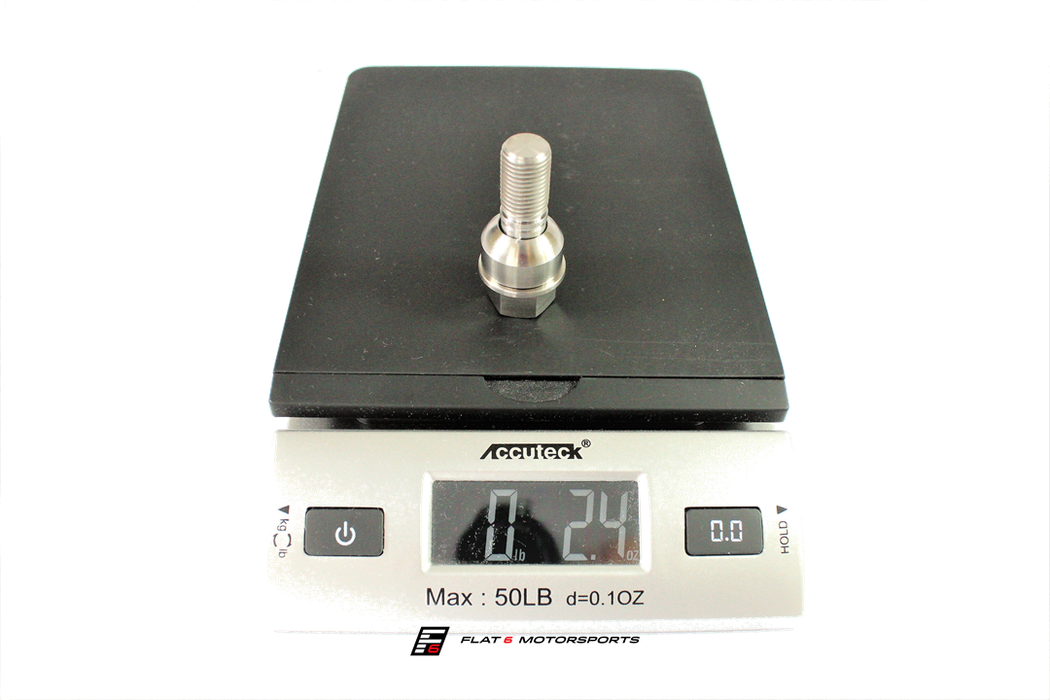

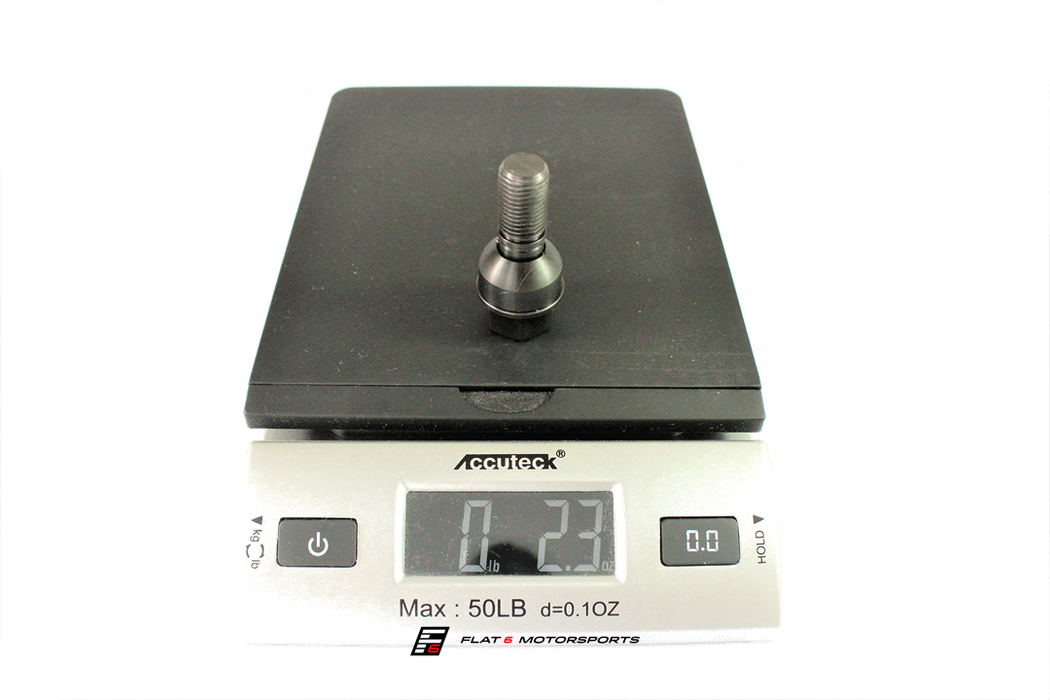

This is a simple replacement Porsche titanium wheel lug bolt set for todays water cooled models. It uses the factory style floating ball seat and utilizes a 19mm head like the stock lug bolt.

Made from aircraft grade titanium 6AL-4V (grade 5), the outstanding benefits are that we roll the threads to produce greater fatigue strength and reduce galling. These Porsche titanium lug bolts are in excess of 120,000psi ultimate tensile strength, suitable to replace both Grade 5 and Grade 8 steel bolts.

Wheel Lug Bolt Features

- 14X1.50 28mm Lug Bolt

- Factory Floating Ball Seat

- All Titanium

- Reduced rotational weight

- Corrosion resistant

- Replaces Stock Lug Bolts

- Simple Installation

- Made in California

Technical Specs

| Density | 4420kg/m3 (276lb/ft3) |

| Young's Modulus | 110GPa (16 x 106 psi) |

| Yield Strength | 828MPa (120 x 103 psi) |

| Ultimate Tensile Strength | 1030MPa (149 x 103 psi) |

| Compressive Strength | 960MPa (139 x 103 psi) |

| Shear Modulus | 43GPa (6.24 x 106 psi) |

| Ductility | 10% elongation at break |

| Poisson's Ratio | 0.34 |

| Hardness | 36 Rockwell C |

| Strength-to-Weight Ratio | 187 kNm/kg |

| Stiffness-to-Weight Ratio | 24.9 Mnm/kg |

About World Motorsports

Based in Los Angeles, World Motorsports is a full service tuning and installation center for high-end European automobiles.

Our customers can rely on us for sales, service and installation of any of the parts that we sell. We also have a full fabrication shop so, providing our customers with services that go above and beyond what any other shop can do.

Our customers include original equipment manufacturers like Mercedes Benz USA, Toyota USA and Scion. The reason we have these customers is because they know that they can rely on us to get the job done and get it done right. When the head of Toyota comes by your shop to see what’s going on, you must be doing something right. The reason we build these vehicles and take on these daunting jobs is because it gives us the experience to deliver the highest level of quality in all of our jobs no matter how big or small they are.

We have all the equipment we need to get the job done. Whether we need to develop a tune for a vehicle or we need to manufacturer a run of highly intricate and detailed parts, we do everything in house. This assures us that our customer gets what they want and receives the level of satisfaction that they have come to expect.