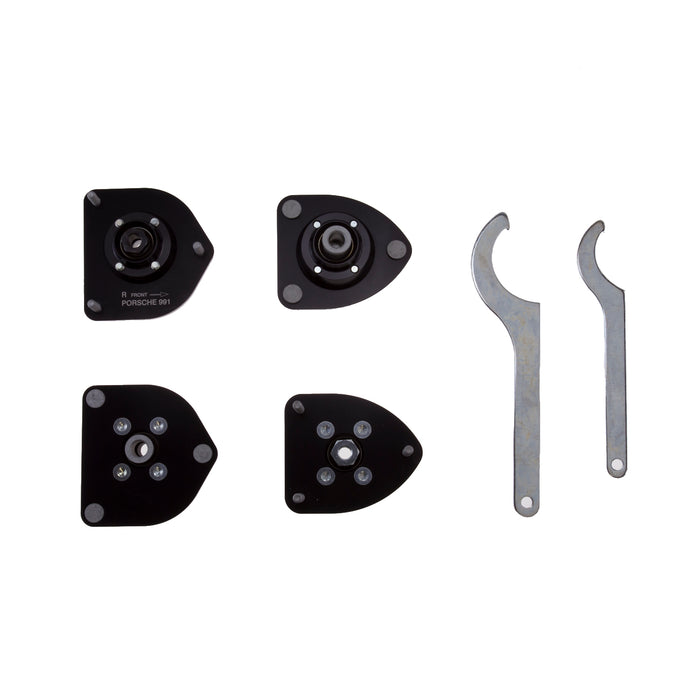

Bilstein Clubsport Coilover Kit (991)

Designed to Fit:

- 2012 - 2019 Porsche 911 Carrera / Carrera S / Carrera GTS / Carrera 4 (991)

- 2012 - 2019 Porsche 911 Turbo / Turbo S (991)

Note - will NOT work with PDCC equipped vehicles.

Product Details:

- Front Lowered Height: 25-35mm

- Rear Lowered Height: 10-30mm

Bilstein Clubsport suspension kits feature ride height adjustability with 2-way manually adjustable dampers in an OE quality, direct fit package. The 2-way independent rebound and compression adjustment features 10-stages each, providing up to 100 different settings for the ultimate in handling performance under any condition. The adjustable monoball upper mounts allow the user to change camber settings to suit any road, condition or driver preference. These kits offer monotube performance dampers with matched springs that are tuned for each specific application. The zinc coated and threaded body design will give you the flexibility to find the perfect ride height setting for your intended use while providing unsurpassed protection against the harshest road elements. Bilstein Clubsport suspension kits are made in Germany and tested under motorsports conditions on the famed Nurburgring.

Features:

- Separate configurations for rebound and compression: Red for rebound, blue for compression

- 100 setting variations that can be manually selected and experienced with tangible differences

- Aluminum adjusters are easy-to-read and scale from 1 (soft) to 10 (hard)

- Simple set-up changes without additional tools

- Camber adjustment with aluminum uniball support bearings for optimal cornering stability

- Weight and installation space advantages thanks to integrated reservoir

- Extremely resilient design includes quality sport springs made of high-strength material, and spring seats and lock rings made of a special aluminum alloy

- Allows further customization for use in racing

- Made in Germany

- Threaded body adjustable range

Resources:

About Bilstein

When August Bilstein laid the foundations for the innovation incubator BILSTEIN in Altenvoerde in Germany's Westphalia region in 1873, nobody had any idea of the crucial influence the company's products would one day have on the driving comfort and safety of cars. Instead it was metal window fittings - sold under the catchy name of AUBI, an abbreviation of August Bilstein - that soon made the company famous far beyond the boundaries of Bilstein's local region and even abroad.

A whole series of technical innovations followed and the revenues earned through these patents provided a solid basis for the later successes of what was still a young company. In order to meet the exacting quality demands already in the preliminary stage of manufacturing the fittings, the company set up its own strip iron rolling mill in 1919. In line with the motto "A rolling stone gathers no moss", Hans Bilstein, who had taken over the running of the company from his father, returned to his native Westphalia from the USA, which in the 1920s was still a long way away, bringing with him new concepts for nickel- and chrome-plating processes.

Entry into the automotive business: 1928-1954

It was in 1927 that Hans Bilstein made the first move towards the automotive accessories industry, through his co-operation with the Berlin-based lifting gear company Levator-Hebezeug-Fabrik. He did not have to wait long to see his activities bear fruit.

In 1928, four years before the opening of the first motorway between Cologne and Bonn, BILSTEIN supplied the first chrome-plated bumper for mass-produced cars. Just one year later the company began producing car jacks. In typical BILSTEIN style, it entered this market with a resounding technical innovation, introducing the first usable side jack to a world that was only slowly getting used to the car. But the true world sensation was still to come.

Gaining the lead through expertise and technology: 1954 to the present day

In 1954, BILSTEIN was the first to realise the potential offered by an idea of Prof. Bourcier de Carbon, a French researcher in the field of vibrations. The aim was to eliminate the physical disadvantages of the conventional telescopic shock absorbers, whilst at the same time making the dampers lighter and able to be fitted in any position.

Enormous effort went into development, accompanied by substantial investment in the necessary production facilities, in order to achieve this ambitious target. And it paid off. The introduction of the first mono-tube gas pressure shock absorber in a standard production Mercedes-Benz vehicle in 1957 by what was at the time the 'Fittings and car jack manufacturer BILSTEIN' (Beschlag- und Wagenheber-Hersteller BILSTEIN) is still today considered a major contribution to active driving safety.

Gas pressure technology is now used in all types of telescope shock absorbers developed for use on powerful, high-class cars. The latest highlight is the development of the air spring module that BILSTEIN supplies 'just in sequence' to the Mercedes S-Class production line.

To this day, the demands of its customers in the automotive and tuning industries, combined with its commitment to motor sports, are what drive development and innovation at BILSTEIN. All AMG Mercedes in the DTM and over half of the teams in the 24 hour race on the Nürburgring approach the starting line with BILSTEIN accessories.

The name BILSTEIN has for many decades been closely associated with high tech in the field of suspension design, driving comfort and safety. In order to expand this position in the future, BILSTEIN became a division of ThyssenKrupp Technologies AG in 1988, and a wholly-owned subsidiary in 2005. The partnership and co-operation within the group will enable the company to continue to inspire with innovations in the traditional BILSTEIN way.