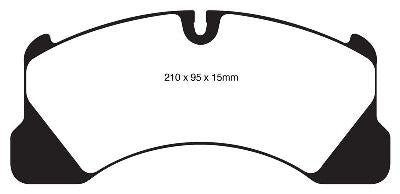

EBC Bluestuff Front Brake Pads (Panamera)

Designed to fit:

- 2011 - 2015 Porsche Panamera (Front)

- 2010 - 2015 Porsche Panamera S (Front)

- 2013 - 2015 Porsche Panamera GTS (Front)

- 2012 - 2013, 2015 Porsche Panamera Hybrid (Front)

- 2010 - 2015 Porsche Panamera Turbo (Front)

See our Panamera Brake Guide for OEM specs/fitment or contact us with any questions

Product Details

Bluestuff Intermediate grade Trackday pads or Bluestuff NDX is a high friction sport and race material that can be used for aggressive street driving and certain types of track use. The material has had much success on the track with quality aftermarket calipers (Multi piston systems with better release and cooling and larger rotors) and limited success with street based calipers where pad size and caliper drag can challenge any brake material.

The biggest advantage of EBC Bluestuff intermediate grade trackday pads or Bluestuff NDX is their bite from cold and progressive brake feel and the ability to bring a car to a complete stop. This has led to the ECE R90 brake safety regulation approval of R90 which is now completed and certificates are being obtained (during July 2011). There are certain older street based caliper systems where even the new Bluestuff Intermediate grade Trackday pads will have trouble handling the caliper and slider drag inherent in the systems but this scenario is exactly the same for our competitors. There is NO material that will be PERFECT on the track in all older street based caliper systems.The NDX pad material is bonded to the steel backing plates using multiple high strength interlock holes and a unique chemical interlayer which raises shear and bond strength by a factor of five and prevents pad to plate separation. The pads are then baked and ground and feature high volume Vee grooves to catch the inevitable large amount of debris from track use.

Target use is all types of fast and heavier cars in performance and race driving with much enhanced lifetime over our previous Yellowstuff grade pads.

The EBC chemical interlayer system is used on Bluestuff NDX range pads which being a harder material and for heavy duty race applications require that extra security of bond strength. The effect of the interlayer is to triple shear strength of a common organic brake pad over non interlayer versions.

About EBC

With a worldwide work force of over 400 people, EBC Brakes is an independently owned and managed leader in the brake market, proud of it’s customers, it’s products, it’s success and its people. EBC Brakes produce the largest range of brake pads and brake discs in the world, with over 5000 part numbers for every type of moving vehicle. EBC Brakes are made in one of its two specialist factories in the UK and USA. The majority of EBC brake discs or brake rotors are also made in the UK.

With modern trends towards cheap imported brake pads and brake rotors, EBC Brakes leads the world in its technology, quality control, product performance and customer service. Our product range includes brake pads for cars, trucks and SUV, brake rotors (brake discs) for every rolling vehicle on the planet and even brake pads for wind farms, brake pads for military applications such as the Humvee, various armoured cars and even tanks, railway brake products and all kinds of industrial vehicle brakes.

Types of brake pads manufactured include aramid brake pads, sintered brakes, ceramic brake pads and carbon long life brake pads. The EBC Brake rotor brake disc range includes cast iron brake rotors or brake discs for automobiles, stainless steel brake rotors for motorcycles, mountain bike brake pads and mountain bike brake rotors and ATV brake pads and rotors.

Over the years the brake market has seen many changes and many brands come and go. We have also seen many so called “Famous Names” resort to Branding products and having them made by licensees in emerging market locations. EBC has strongly pursued its philosophy that brake pads and rotors are safety products, and are best hand crafted to maximum focus on high quality rather than price savings and are designed and researched on an on-going basis in our own facilities rather than turning a high safety product into a commodity marketed price point product. We firmly believe that saving a few pennies on brake pads and brake rotors is false economy.