Soul Performance Products - Competition Headers (992 GT3 / GT3 RS)

Designed to Fit

- 2020+ Porsche 911 GT3 / GT3 RS (992)

- Direct replacement of factory headers on 992 GT3 / GT3 RS with stock rear exhaust

Product Details

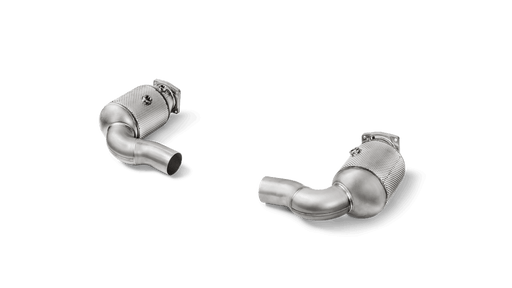

SOUL Competition Headers are designed around long tube runners and a billet CNC’ed merge collector to maximize the performance and sound of the 992 GT3’s 4.0-liter flat-six.

Even with the 992 GT3’s elite motorsports pedigree, regulations and external pressures forced compromises to be made. Primary tubing length, runner diameter, and merge collection efficiency are limited even in the most purpose-built of applications, and these compromises come at the cost of sound and power. That’s where we come in.

For immediate results, addressing the restrictive factory headers is the place to start, where the assembly houses catalytic converters and particulate filters—naturally stymying the flow of exhaust through the system. Our replacement is built with optimized cast flanges and runners for maximum gains in power, throttle response, and tone from the 992 GT3’s 4.0-liter flat-six. The resulting sound change is a significant amplification of the system mounted rearward, a proper emphasis on the flat-six’s sound as intended, and built to withstand aggressive driving in the most demanding environments.

HEADERS: For those individuals looking to maximize performance, shed over 25 lbs, and realize full sound potential a complete race system is a logical conclusion. Removing the heavy and restrictive factory headers is central to the performance improvement. By pursuing a full system replacement we can eliminate the restrictive cat assemblies, the “particulate filters”, and the giant 7 ⅝ connection point to the factory rear muffler assembly. A simple flange optimization to our previous generation GT3 Competition Headers allows us to get rid of the factory 991 gen connection point requiring costly OEM clamps and donut gaskets and utilize a more efficient v-band connection point.

CONSTRUCTION: Each component is assembled in the USA out of mandrel bent, thick wall .065″” T304L stainless steel. Our billet 304L stainless steel head flanges and merge collector are precision cut on a 5-axis CNC machine for the best possible exhaust flow and strength. Back purged TIG welding (with ARCAL™ Prime argon gas) ensures proper weld penetration and longevity – crucial for durability on the track. We fabricate the headers and system using thick gauge aluminum fixtures which act as a great heat sink during the welding process and prevent warping not only of our products, but the fixtures themselves to ensure perfect fitment.

BOLT ON AND GO: Every set is rigorously quality-checked prior to shipping and then foam packed to ensure your order arrives in perfect condition.

LIFETIME WARRANTY: Enjoy your SOUL exhaust components with confidence on both the street and track as they are covered for life! Soul covers their HJS catalytic converters with a 3 year warranty while the headers themselves are backed by their lifetime warranty.

NOTE: This product is not CARB certified and may not be legal for use on emissions controlled vehicles; intended for closed course competition use only.

About Soul Performance Products

Our mission is to provide our customers with outstanding parts, pricing, and service backed up with the best warranty in the industry.

Soul Performance was formed by a team of auto enthusiasts with automotive industry experience looking to do the right thing by our customers. We aim to deliver exemplary service worldwide by developing incredible sounding, proven performing components that are always ready to ship to you quickly.

CORE VALUES

- Do right by our customers, always – no customer left behind

- We believe in honesty, unwavering ethics, and transparency as we operate

- Our product warranty extends longer and broader than our competition

- We actively participate in the communities we cater to

- We build connections to further our ability to deliver a premium experience

- Our passion for cars and the automotive industry drives our business

- Our experience helps us meet your expectations

- We listen to our customers and the demands of the market to meet and exceed expectations

- We want to be our customers first choice without hesitation

- We consider both quality and pricing to deliver greater value to our customers

- Our success will be measured by recommendations to other potential clients

FACILITY Soul Performance Products is located in a 15,000 sq ft facility north of Philadelphia in Willow Grove, Pennsylvania. We make great use of this space to keep our products in stock, ready to ship. Our mission is to quickly get you the parts you need with no delays. Our R&D area is equipped with two BendPak lifts and all tools necessary to allow us to design, engineer, test, prototype, and fixture components. Our shipping area is set up to ensure that all components get a thorough inspection, orders ship complete with all hardware, and that products are well packed.

Nearest hotel: SpringHill Suites by Marriot – .3 miles Nearest airport: Philadelphia International Airport (PHL) – 36 miles

MANUFACTURING Soul Performance Products is partnered with ISO 9001 Certified aerospace manufacturers, enabling us to work with technology and industrial scale, extreme precision equipment down to +/- 0.002 inches that would otherwise be out of the limits of an exhaust manufacturer. Our capabilities include waterjet and laser cutting, tube bending, CNC machining, robotic welding and much more. We strategically deal with vendors worldwide to find appropriate components, such as high quality HJS HD catalytic converters. Our mission is to provide the best possible results for our customers at great pricing.

If you’re interested in participating in new product development or have any customization desires we’re always happy to accommodate wherever possible. Need custom exhaust tips to match your unique build? We can do that.

PERFORMANCE We’re constantly building relationships with shops across the world to prove our products on various dyno setups under different conditions. We don’t want you to take our word for it alone, but allow us to validate ourselves through multiple outside channels as well. If you’re interested in testing our components, do contact us.