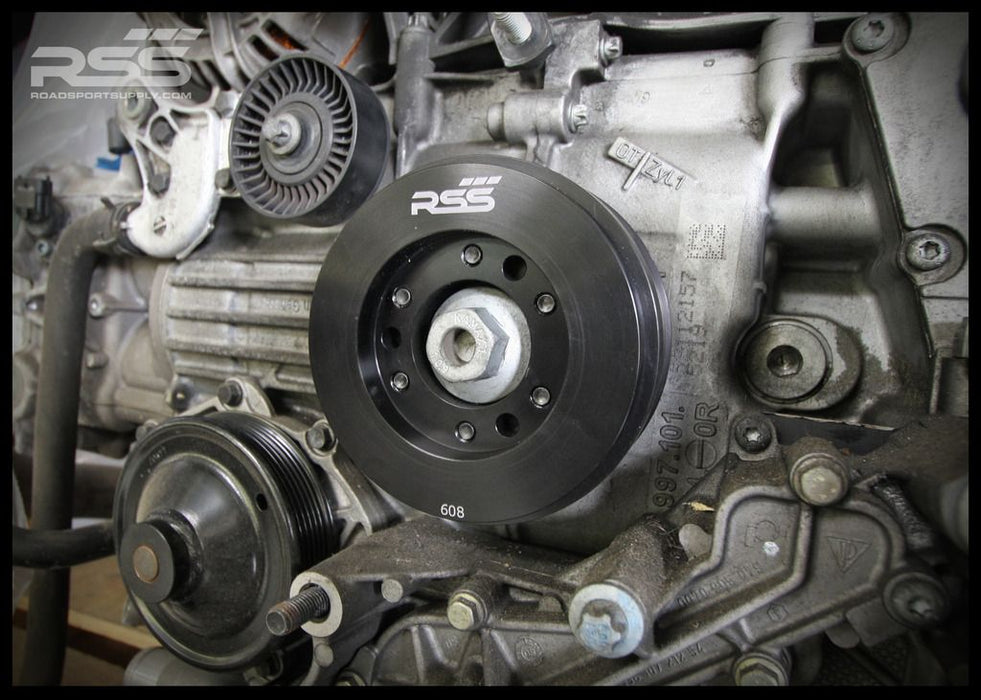

RSS Performance Harmonically Dampened Underdrive Pulley Kit (996)

Designed to fit

- 1999 - 2005 Porsche 911 (Except GT3, Turbo models)

Product Details

The RSS Harmonically Damped Underdrive Pulley is ideal for engines that are running light weight flywheels, engines that are built - bored/stroked and engines that are driven hard.

- Offers improved HP & TQ by reducing drag from the power steering pump, A/C, water pump and alternator without detrimental effects on said ancillary systems.

- Dampens/reduces internal engine harmonics for improved engine performance, efficiency and longevity.

- Recommended for street or track use

Fits on all Porsche 986, 996, 987, 997 models EXCEPT 2.9L, DFI engines, GT2, GT3 and Turbo.

Installation tool (wrench) and new OEM Pulley Washer included.

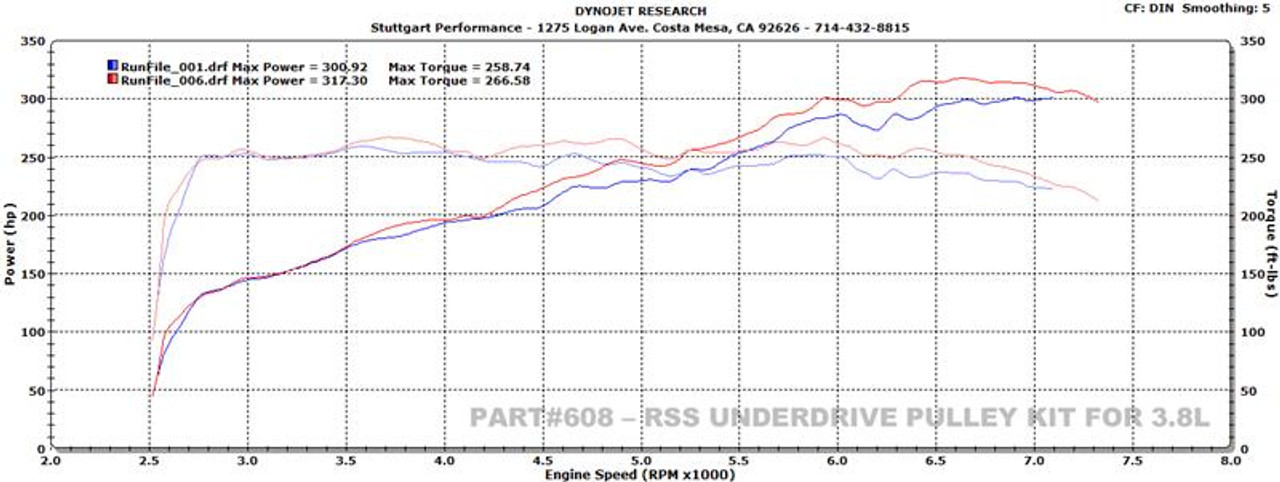

Dyno Image shows HP & TQ gain on 2005 997.1 Carrera S:

Baseline Dyno Run Mods: OEM Crank Pulley, OEM Software, Cargraphic Headers, Hi flow 200 Cell Cats, and Medium Sound Cargraphic Sport Mufflers

Modified Dyno Run: Added RSS Pulley (Part #608) to baseline car with existing mods:

+16 HP / +8 ft lbs TQ

*NOTE: We recommend using/sourcing a new OEM Crank Shaft Pulley Bolt for your specific vehicle when installing the RSS Pulley. (Not Included with 608 Kit)

Appropriate length belt sold separately.

MADE IN USA

About Road Sport Supply

RSS – Road Sport Supply is owned and operated by a passionate team of motorsport professionals focused on performance driven design, engineering and manufacturing. With over 28 years of experience in the performance aftermarket, RSS is uniquely structured to meet the fast paced schedules and demands of the enthusiast tuning and racing community. Stuttgart Performance is the in-house RSS Motorsport R&D Division. THey continue to play an important role in Southern California's trend-setting European car culture and lifestyle.

Unlike current trends of outsourcing and private label, RSS is a genuine manufacturer. They design, engineer, and create their products on premises using advanced technologies in 3D design, 3D scanning, stress analysis, rapid prototyping, CMM inspection, CNC machining, robotic automation, waterjet cutting, tube forming/bending, metal fabrication, metal testing,

and a variety of finishing techniques.

They've expanded to over 65,000 sq.ft. at their headquarters and factory in Costa Mesa, CA. They are proud to be manufacturing in the USA. With a primary focus and true love for Porsche automobiles, they produce some of the finest performance upgrades and motorsport components available.